Learning to become a Certified SOLIDWORKS professional? Get sample exams, tutorials & online training now.

Recently I found myself looking at some of our current products, which are made of sheet metal. My experience with sheet metal is minimal and as I go about modeling these parts I want to use all the features I am used to. Having worked primarily in plastic part design this is difficult as many sheet metal features are difficult to show. Thankfully the built in sheetmetal features will solve this problem but I’ll need to figure out what they all mean and how to use them. So now it seems time to do some studying. The goal here will be to pass the CSWP-Sheetmetal Exam. From Solidworks:

The completion of the Certified SolidWorks Professional Sheet Metal exam shows that an individual has successfully passed a skills test that demonstrates their ability to use the sheet metal tools inside of SolidWorks. Employers can be confident that an individual possessing this certification understands the set of tools inside SolidWorks that will aid in the design of sheet metal components.

A sample test for the CSWP-Sheet Metal exam is provided by Solidworks as a study tool but

first up I’m going to run through the tutorial built into the software. Here is what it says I’ll learn. The CSWP-Sheetmetal Test covers a few other things as well. I’ll review them in subsequent posts (linked below) but first what’s to learn from the tutorial.

The CSWP-Sheetmetal Test covers a few other things as well. I’ll review them in subsequent posts (linked below) but first what’s to learn from the tutorial.

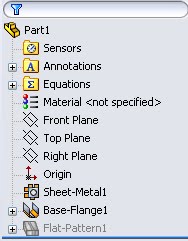

The first thing to note about Sheetmetal is that there are a lot of variables. This is evident by the start of the design tree. To start any sheet metal part a base flange is created which, after first created, actually inserts 3 features into the feature tree. These contain information for the material being used (thickness/gauge), how it will bend (bend radius), the base sketch, and a layout of how the part will fold flat (as sheet metal is made out of a flat sheet).

Having these features also sets up some new parameters in other functions. Linking features to the thickness relates back to the value saved in sheet metal, this can be seen in extrudes and cuts. The rest of the tutorial course helps you build out the rest of a basic part and create a drawing for it. Most features are used but can be glossed over by entering simple values in a few places. Taking the time to understand each one individually seems more productive so I’m going to take a look at the required features one by one. Again, direct from Solidworks, those are:

Exam features hands-on challenges in many of these areas of SolidWorks Sheet Metal functionality:

Finish up the study, take a look at the practice exam and it’s time to get a certificate.

**Edit**

As I have gone through studying for this test I keep finding more and more helpful resources, not one to hide good information I will include them below. Some of these are outdated tutorials but still helpful.

Solidworks Resources for teachers- Sheet metal.

Become a Certified SOLIDWORKS professional fast. Get tutorials & online training now.