This article is a guest post by Jim Lucas

A few confessions of a competitive guy that has average intelligence and mediocre athletic abilities:

- In my college organic chemistry lab, I would increase the quantities of the ingredients, because a component of our grade was the overall “yield” of lab work.

- In lacrosse, I kept a notebook with the referee’s names and my observations on their habits of whistling the start of the game (I was a face-off midfielder, and would try to get the jump on whistle).

- I have always done every sample test I can get my hands on. While I haven’t ever formally documented a “trend” study until now, I think I subconsciously always did one.

Ideally, tests correctly measure the abilities of the participants. The reality is that you can gain a distinct advantage by understanding the environment and conditions of test. Let’s spend a few minutes inside the head of Mark Schneider, the Dassault mastermind behind Model Mania.

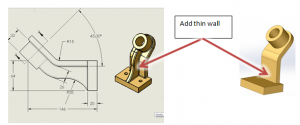

- Everyone (even newbies) could do it knowing basic SolidWork Skills, but it correctly separates the people who are fast. So, there shouldn’t be any obscure feature that MUST be used in order for it to work. It should be features that make life fast & easy. For example, in MM2001 there was a strengthening thin wall that was specified.

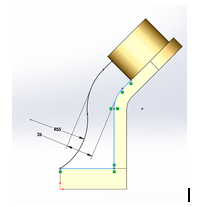

So, to build this, first you start with a sketch

FROM THIS POINT, you could go a couple of different ways: The hard way… Close the sketch.

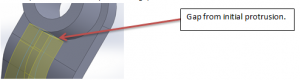

Make a protrusion, realize you have a gap.

Then, either go back and extend the sketch into cylindrical boss, or find some other way to fill the breach. The easy way… Use the rib feature.

So- you need to have a good grasp of the common features, but you also need to know how to features that make things easy. Other tools that fall in the category: Draft, various Patterns, Delete Face, Intersect (using multi-bodies).

- This exam should highlight the new features and changes in 2014. This needs a whole separate article devoted just to it. I’ll work on that later this week with the trend study.

- You are at SolidWorks World. They want to showcase their flagship product. When this gets presented on Wednesday, the part should be a relatively complicated geometry that is built easily (and then quickly modified if modelled correctly). So there shouldn’t be any “resolving failure” mode or more than a dozen items in the model tree. The detailed part drawing should comfortably fit on 1 sheet of paper. Like I said in my last article, this isn’t a “gotcha!”-type question.

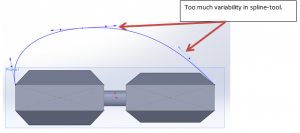

- There can be no ambiguity to the part. So there will not be a feature that could either be a COMPLEX boundary OR a loft (resulting in slightly different geometry). There won’t be anything using splines.

So the part needs to LOOK complicated but be easily defined with a handful of dimensions. When you see this limitations, you’re able to cut down on the type of tools you freshen up and study. And this is a living document. Let me know if you have anything to add.

Jim is a CSWP and on the road to getting his CSWE. He works for HawkRidge Systems, an authorized reseller of SolidWorks. Jim also runs i-elf, a product development consulting company. He can be reached at Jim.Lucas@i-elf.com.