This article is a guest post by Jim Lucas

First week of training is done. When I first started, I had the youthful optimism that, with a little work, I might be able to sweep the Model Mania top award easily. It doesn’t appear that will be the case. My times are all over 10 minutes. In some instances, I don’t finish in 20 minutes.

Participating in SolidWorks World Model Mania is like going from high school ball to NCAA Div 1. The people that go to SW World are HEAVILY invested in the program with tens-of-thousands of hours under their belt. I might be pretty good in my small hometown but this is like going to the Olympics. I should be jazzed to be on the same playing field.

Forget what I said in my last article about being ready in a month. It’s time to adjust to my expectations:

- Don’t worry about winning, focus on learning.

- Figure out how to be a better coach. I appreciate you reading these articles, and I hope they are beneficial. The other people I teach/coach are a bunch of high school robotics students. It’s unfortunate that I can’t bring them. I’m still a bit faster than them, but they are catching up QUICK. Just by practicing, I have some great new lessons planned for them.

- Narrow my playing field. If I beat my buddies, that’s good enough for me. I know that goes against what I said in #1… oh well. That’s just my nature.

The Model Mania Setup at Solidworks World

For those doing this for the first time, here’s what you can expect regarding the “testing situation” of model mania.

- SolidWorks sets up Model Mania in the partner pavilion – the “trade show” where partners and exhibitors show their wares.

- Curtained booths set up towards the back of the room. Sometime during the time the partner pavilion is open (which is mostly lunchtimes and afternoons during the conference – but before Wednesday morning, when they announce the winners), you roll up to the friendly SolidWorks TTM running the model mania booth that day and say “I’m interested”.

- They give you a drawing on a laminated sheet, a part, and lock you in the booth. You have 20 minutes to finish the next two steps.

- You model the thing as fast as you can. When you’re happy, you yell out to the TTM “I’m done!”.

- They hand you a drawing change on another laminated sheet. You adjust your model, and they’ll also spec a simple simulation analysis. They ask you to input a certain result as your “answer”.

- All correct files get reviewed (the first cut is they check your mass props and sim result, then they review your model practice). The files, your time and your result get stored, and the machine is reset for the next guy.

I believe you can take a few minutes to configure your environment prior to receiving the first drawing. I’ve never done this. Not sure about bringing in settings files, but it can’t hurt to have it on you. I’m going to check on it, because I’d rather practice in the same environment as I’m testing in.

Before I got started my training for 2014, I wrote down my “to-do” list… a plan of action. After doing a few problems, here’s what I’ve come up with a “to-don’t” list:

Top 3 things to avoid during Solidworks Model Mania:

- Don’t rush your attack. The first 2-3 minutes of reviewing the problem are critical- and it’s free time. Bring a pen & pad and write down how you plan on making your model. You should know the first 3 features before you even sit down at the computer. What will be your first sketch? Do you have all the dimensions you need to fully define it? Drawing interpretations is key. Don’t assume that you’ll figure it out as you go along. In a way, it reminds me Harvard Business case study challenge where groups of students were given Legos to build to a certain specification. They spent hours planning how to put the assembly together and then seconds to assemble everything. I would have probably ripped the bag open and just started assembling. I need to resist that impulse.

- Don’t get stuck in a rut. This is where you have no idea how to finish fully defining a sketch, or incorrectly/inefficiently define it. After doing a few of these, I seem to have this figured out. You know the “Model Items” command in Drawings (if you don’t- look it up… it’s super useful). Make the part that will produce a drawing that will create the dimensions on the test sheet using “Model Items”. Here’s an example of where I messed up on MM2001. When I was trying to figure out how to make this, I thought I’d start extruding the “backplate”. I got fixed in that train of thought, and this model got a LOT more complicated to make. Try it out. The provided dimensions are just not conducive to that step. If you do a revolve for the top bit, it falls into place MUCH easier. A lot of this is making sure you nail #1, and have a good plan.

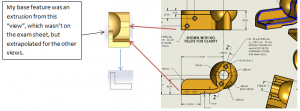

- Don’t get fancy or clever. I got destroyed on MM 2003 because I tried to “out-think” it. Don’t do this: My base feature as generated from a view that wasn’t there. Not only did I take miserably long to make the first part, but the change in “Phase 2” was a complete disaster. This test isn’t going for a “gotcha”. It’s tough, but straightforward. One of my few strengths is dealing with shenanigans and, unfortunately, this competition doesn’t play to that ability.

Let me know how it’s going for you!

Jim is a CSWP and on the road to getting his CSWE. He works for HawkRidge Systems, an authorized reseller of SolidWorks. Jim also runs i-elf, a product development consulting company. He can be reached at Jim.Lucas@i-elf.com.