|

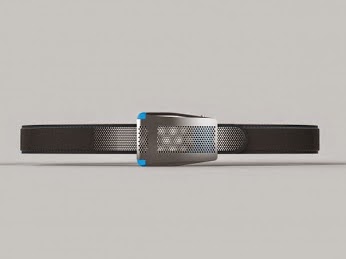

| The emiota smart belt – straight off a 3D printer |

The luxury goods market spans across several categories and include haute couture clothing, accessories, luggage, yacht, cars, hotels… Its value has risen significantly in recent years. The biggest challenge for the luxury industry is to attract the increasingly diverse and sophisticated consumer base, by providing clients with a truly unique experience. New styles, new cultures and upmarket creativity can no longer stand traditionalism and main stream. Luxury needs innovative manufacturing techniques as 3D printing. 3D printing sites are getting more and more popular and the accuracy of their services is astonishing.

Additive Manufacturing was successfully adopted by two groups of luxury goods. Haute couture clothing and shoes are everywhere to see at the latest fashion shows. The shoes industry is actively experimenting with 3D printing to manufacture functional insoles and new technologies for a lighter and stronger baseplate as the Vapor Laser Talon from Nike. The second group includes all kind of wearable smart electronics as smart watches and even smart belts as emiota – the self-adjusting belt with a 3d printed buckle and an assembled knurled shaft.

Benefits of ALM for the Luxury-Goods Market

Fast Production

A 3d printed piece can be created with a touch of a button. The STL file is sent to the printer which needs a few minutes to do its magic and print the desired object. If a revised version is required, the code can be altered immediately. This means a lot for the on-demand orders of big, expensive brands. Instead of making wealthy customers waiting for a week or two for the next delivery of this exceptional smart watch, sunglasses or golden ring, the staff can simply print a new one. It sounds as a cheap fast done replication of something precious, but it is not. Additive Layer Manufacturing techniques deliver most precise results and are especially suitable for the production of very small pieces with a complex geometry.

Customization

An exclusive clothing piece, jewelry or even a pair of shoes can be easily altered to fit the size of the customer. Or even better: the customer can be offered the option to design his own,uniquesmart watch or high heels, 3d printed in a precious metal.

Creativity

Haute-Couture collections and luxurious accessories design have always played with the limits of extremes and promoted creativity through constant innovation. And even though many creators see the end of their craftsmanship approaching with the 3d printing industry, the huge opportunities that Additive Layer Manufacturing offers to the luxurious fashion world can’t be ignored. First it provides a high level of exclusivity and personalization and second it generates new culture and styles.

Environmentally friendly

In the jewelry business 3D printing can be used to create a piece with an upmarket design or to cut precise pattern and mold, used for the creation of the fine jewelry piece. This significantly minimizes the raw material waste. The potential to recycle contributes to a better environment and reduces cost. Printing on textiles is already possible and very soon we might be able to print bioengineered leather with the same characteristics as a product made of a hide.

Possible Obstacles

Cheap counterfeit goods are the biggest fear of the luxury industry, especially fashion and accessories. If today the entrance of counterfeit goods in the European Union and North America is successfully controlled and can’t be considered as a real danger for the market thanks to the intellectual property laws and restrictions, this situation might change.

The decreasing prices of the 3d printers and their constantly increasing processing speed make them a very attractive purchase. This could easily result in cheap counterfeit goods or replicated logos, attached to cheaper products, made in advanced economies.

However, considering the fact that in the near future producing almost anything from a 3d printer will be possible, the clash between synthetic imitations and designer accessories is inevitable. Even if this could totally disrupttheir business model, luxury brands cannot escape from the invasion of Additive Layer Manufacturing and the reason is simple: ALM has too many advantages to be ignored. The forward-looking luxury companies should accept ALM and enable the 3D printing of their own products by implementing diverse technologies for brand identity, copyright and trademark protection.

Ralitsa Peycheva is a technical content writer, interested in forging and casting techniques, latest machinery and tools; curious about new manufacturing methods; respecting high-quality engineering; discovering, observing and admiring the additive manufacturing industry. Follow her on Google + https://plus.google.com/u/0/+RalitsaPeycheva/posts