Once a parting line has been selected for a part the next step is to create a parting surface. Luckily this step is very easy if don’t in the correct order (ie. if the parting line has been created).

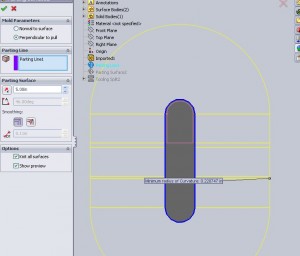

Click the parting surfaces tool and the feature manager will pop up and the parting line is pre-selected. There are a few basic features that can be checked on/off for the feature and this is again one where checking the help files and simply clicking each one and watching the “preview” will be the easiest way to understand the options. For the sample exam most of the selections are irrelevant as they do not change the resulting surface.

Basically here I selected a perpendicular to pull surface. When designing a mold or insert it is important to note that it will be easier to fabricate and machine a tool with flat surfaces. This is rather obvious when considering that mold bases and inserts are sold as rectangular blocks. As a rule of thumb the largest area of flat surface or surfaces flat surface on a part will be perpendicular to the pull of the tool.

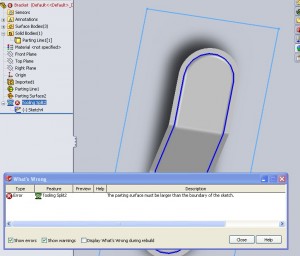

The one item that does make a big difference is the “Distance” field, where the value will need to be great enough to accomodate the dimensions of the cavity. Without creating a large parting surface the split tooling feature (which requires a sketch entirely within the confines of the parting surface) will fail to create core blocks.  Thankfully a massive over sizing here will not hurt performance to much so I tend to just throw in a huge number and be done with it.

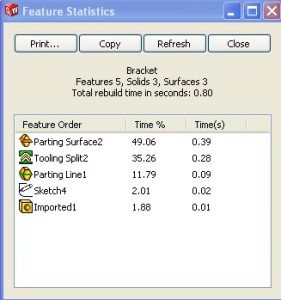

Thankfully a massive over sizing here will not hurt performance to much so I tend to just throw in a huge number and be done with it. Here in the image above I used a distance value of only 5 inches. Just barely enough to allow for the proper creation of the cavity/core blocks. Below however the distance used was 25 inches. Massively oversized and with plenty of room to work. In both the parting line surface feature is the most resource intensive of the few features but the overall difference between the two is minimal.

Here in the image above I used a distance value of only 5 inches. Just barely enough to allow for the proper creation of the cavity/core blocks. Below however the distance used was 25 inches. Massively oversized and with plenty of room to work. In both the parting line surface feature is the most resource intensive of the few features but the overall difference between the two is minimal.

Parting Surfaces can also be created at odd angles to the pull direction. Again testing out the settings by trial and error (and watching the preview) will show what each does. The main idea of the parting surface though is to create a surface that is used to split core blocks.

More review for the CSWP Mold Tools exam.

More on all of the CSWP Exams and preparation.