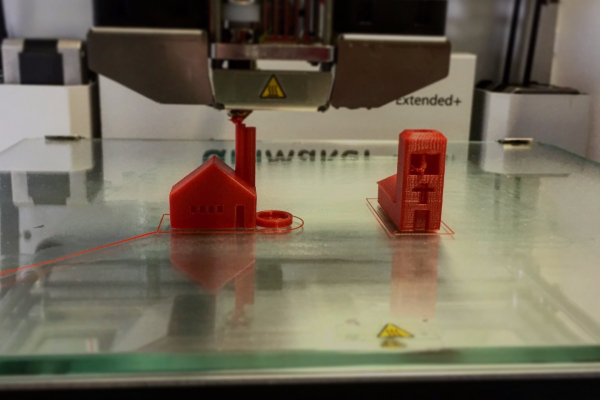

3D printing is also popularly known as additive manufacturing or rapid prototyping. As the name suggests, 3D printing can create 3-dimensional objects. It is the process in which the CAD (Computer Aided Design) is built in a layer-by-layer manner. 3D printers create the objects by scheming the placement and adhesion of the layers of a suitable material.

3D printing is a developed technology that makes it possible to create an incredibly intricate form of the prototypes and products which would not have been possible with the other manufacturing procedures like milling or molding. However, it is really very expensive or practically impossible to create large 3D print structures with today’s technology of the 3D printers that are accessible in the market.

However, 3D printing has been around for several decades but has gained prominence in the recent years. Today, with the technological progression a lot of change and modification seen in the 3D printing technology and is emerging as a new generation technology. The technology application of the different 3D printers varies from each other. The different technologies that are used by the 3D printers for creating the prototypes are (SLS) Selective laser sintering, (FDM) fused deposition modeling and (SL) stereolithography. However, the key function of the 3D printers with different technology remains to bring the create prototype models and end products.

Because of the unlimited customization possibilities and efficient results, the 3D printing technology is becoming more and more popular across industries as a designing tool.

At first, 3D printing was used as a quick solution for prototyping to create a few samples giving the designers and manufacturers a chance to modify the product and correct the errors in the design is required. Still, 3D printing is widely used for the prototyping, but with the progression in the technology it is now possible to use the 3D printing technology in the manufacturing apart from the research and development. Because of various reasons, 3D printing technology has swiftly become popular across different industries and even holds greater potential and promises for the future.

3D Printing Application in Different Industry

The applications of 3D printing are endless. The key application of this technology is creating commercial prototypes that allow the designers and manufacturers to identify flaws in the design quickly and make changes inexpensively. Additionally, 3D printing is also revolutionizing the healthcare industry; it is widely used to manufacture hearing aids, crowns, bridges, and prostheses as well as educational models for the medical professionals.

It is imperative to understand that 3D printing is a fast evolving technology, which offers the set of benefits. It is considered to be a next generation manufacturing technology that is still evolving. Below are discussed a few advantages to understand where this revolutionary technology will be headed in the future.

- Creating intricate Designs– 3D printing will let the manufacturers create intricate shapes and designs that cannot be made using conventional manufacturing procedure.

- Customize the Design – 3D printing allows the easy customization of the digital designs irrespective of the complexities involved in it and without any additional expense of manufacturing process to create the product.

- Requires Less Tools– when creating the prototype or final product it requires less tools and applications in manufacturing procedure, unlike the traditional manufacturing procedure.

- Fast Prototyping– with 3D printing it is possible to create a model quickly which helps the designers to make changes in the design with the feedback received

- Intricate and Quality Designs- With the help of this technology, intricate design of any shape and size are possible. Additionally, it helps reduce the chances of the manufacturing faults and created the better quality products that look very close to the original product.

- Less Wastage- in comparison to the traditional manufacturing process, in 3D printing there is less wastage of the material as well as the products manufactured are lighter and have a sturdy built.

- Diverse Material for Manufacturing-With 3D printing it is ideal to create the objects with high-quality. using diverse materials like metal, silver, ceramic, paper etc.

- Environment-Friendly – 3D printing utilizes less power and creates less wastage for the reason, it is considered as a sustainable technology for future.

In the present times, more people and industries are getting access to 3D printing. With the availability and access to the technology, it will be possible to create customized products as required. The 3D printing advances have opened avenues of new ways of manufacturing products. The industries are extensively taking the advantage of this technology to get a competitive edge and expand their business. The acceptability of 3D printing clearly shows that it extends beyond boundaries within the fields of manufacturing and technology.

Each technology has its strengths and weaknesses that need to be measured. Day by day a new innovation comes out and it is expected that 3D printing might emerge as a billion dollar market. Since the market is big enough and with the continuous progression and improvement in the technology and the high competition in the market, the prices will decline and offer more benefits in the manufacturing of prototypes and end products in the quickest and efficient manner ensuring more accuracy than ever.

Author Bio: Stuart Ting, Owner of Infinity 3D Printing which is one of the largest suppliers of 3D printers and filaments across Australia. He loves to share information about 3d printing technology.

What do you think are the most immediate promises or potentials of 3D printing…now and into the future?